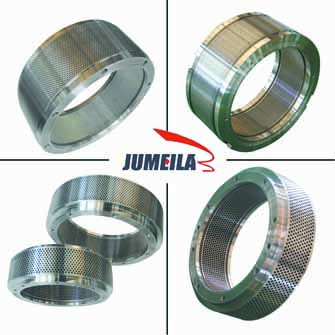

Rich experience

Seiko production

No worries after sale

Enquiry hotline

+86-13961486195

Our quality control

1: raw materials: by now DIN X46Cr13, ESR forging.

2: detection: the element composition of the spectrum, the internal structure of the flaw detector, the test of the hardness of heat treatment, and the precision of the finishing process under the control of the European standard.

3: equipment:the whole NC gun drill processing, including the release hole is also the drill processing. The German TBT imports directly, and the hole finish is controlled within 0.6U.

4: heat treatment is made by CPM process to ensure stable and uniform quenching, and the hardness error is less than 1 degrees.

At the same time, the process of grinding after heat treatment is the same as the concentricity of the inner circle.

5: the whole production process to carry out dynamic circuit inspection, to ensure that each process is qualified to enter the next.

6: our production of ring mold is customized according to the requirements of customers, which can solve the problems of long and short particles, loose material and low output, so as to achieve high quality and high yield.